From brushed to RDrive brushless AC motor

First-ever electromotors, dating back to the early nineteenth century, produced unidirectionally oriented moment of force utilizing mechanically engaged elements. As technological progress picked up pace, motion engineers have got rid of the mechanics, replacing it with solid-state components to build a brushless AC motor. So, what are the benefits of the modifications?

Brushed vs. brushless motor

To understand the basic distinction between the two technologies, it is essential to know their structural and operating particulars.

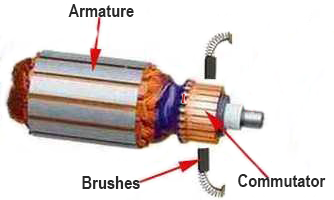

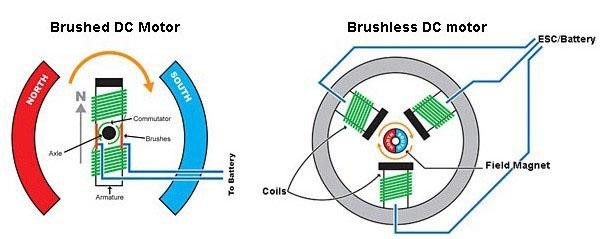

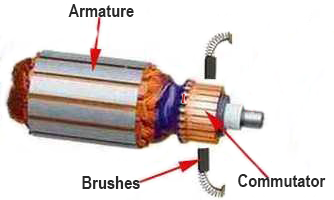

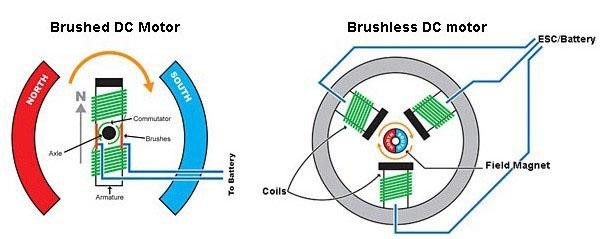

A mechanically commutated engine comprises a rotating wire-wound armature and a fixed-in-place ring with electromagnets or permanent magnets. In addition, the device includes a commutator, a shaft-mounted cylinder linked to the armature winding, and a couple of brushes, typically made of non-hard conductive substances (e.g., graphite).

As the armature is energized, a magnetic field is generated, making the rotor turn. The rotation continues in the same direction for half of the full circle, at which point current has to be reversed. This is the zero-torque point where brushes come into play, interfacing with the commutator to switch current. In this way, rotating motion goes on without interruptions, thus enabling the engine to produce torque continuously without changing it direction.

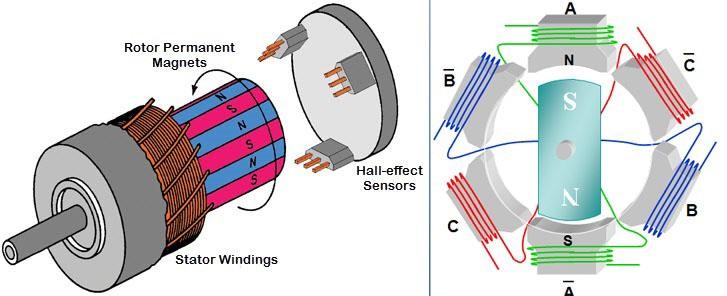

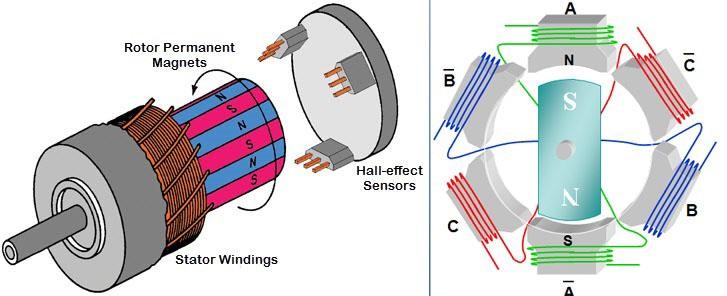

A brushless motor is identical to the previously described class in that both engines have moveable and stationary components. Namely, a rotor and a stator. However, brushless drives, in full concordance with the name, have no brushes to provide commutation. Instead, engines of the type are fitted out with semiconductor-based transistors.

Since mechanically engaged elements are no longer there to commutate, power is fed immediately to the stator coils, where it creates an electromagnetic field. Rotational movement results from the field interacting with the rotor magnets. Once the half-turn reference is reached, transistors do the job of reversing (or disconnecting) amperage, producing torque in the same direction.

What are the benefits?

Major improvements achieved through replacing the mechanics-based commutation with solid-state electronics are associated with the following characteristics:

- size

- efficiency

- admissible speed range

- safety

- duration of life in service and maintenance costs

- disturbances due to electromagnetic induction and loudness of operation

- usage and regulation flexibility

The table below summarizes how brushless solutions compare against brushed engines based on the above specifications.

|

Using brushes to commutate

|

With brushless commutation

|

|

Bulky because of the mechanical contact arrangement adding to both size and heft

|

Trimmed in weight and dimensionally after removal of the commutator assembly

|

|

Rubbing of sliding contacts leads to substantial loss of capacity

|

Notably high power-to-mass and torque-to-mass ratios

|

|

The admissible maximum RPM is limited due to the mechanics-based design

|

Minimal rotor inertia enables motion at higher velocities

|

|

Sliding contacts cause sparks; safe only in explosion-proof and non-flammable atmospheres

|

Spark-free operation due to mechanical commutation replaced with electotransistors; safe to operate even in potentially explosive environments

|

|

Graphite commutating elements are easily worn out, contaminating the insides with dust

|

Reduced maintenance requirements and cost due to absence of wearable parts; enhanced durability with the operating resource tied only to bearing life

|

|

Sliding contacts engaging with the commutating unit sound rather loud and generate considerable electronic noise

|

Quiet operation and decreased electromagnetic interference

|

|

Perform best at slow rotation rates, with torque degrading as a motor accelerates; simple velocity control

|

Complex controlling logic, but extended capabilities to regulate motion, such as microstepping, holding torque delivery, etc.

|

From the comparison, brushless servomotors look way better, fist of all, in terms of compactness and performance. However, mechanically commutated drives boast cheap price and simplicity, whereas the brushless type needs complex control arrangements and runs high risk of demagnetization at increased temperatures.

AC, DC and other configurations

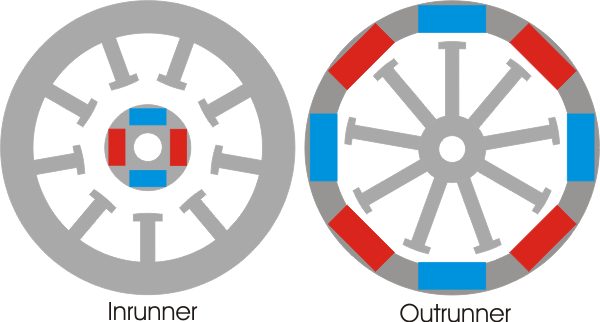

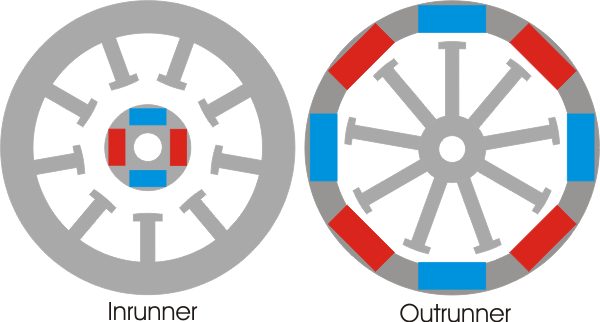

Accounting for structural particulars, it is possible to subdivide brushless motors into outrunner engines and inrunner drives. In an actuator of the inrunner variety, a rotor ring fitted with magnets revolves inside a stator that fences the ring around. In outrunners, stator coils are fixed in place at the core of the assembly, whereas the rotor is on the outside and rotates.

As a rule, inrunner engines are smaller in diameter than the other type, but have a longer body. In terms of performance, outrunner drives deliver lower rotation rate per volt (Kv in specifications). Since Kv is in inverse relation to torque, outrunners generate larger moment of force quantities. Inrunners boasts better heat dissipation, demonstrating optimized efficiency as compared to the outrunner category.

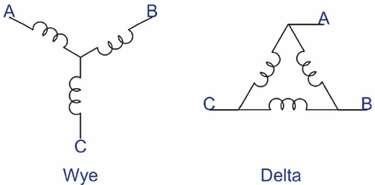

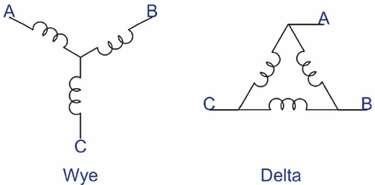

According to the winding type classification, brushless motors incorporate coils of either Delta- or Y-configuration. In the Delta configuration, motor phases are wired together, with current supplied to the points of contact. In the Y-type winding (also known, as star), phases meet in the centre. In the delta configuration, torque delivery degrades as speed decreases, whereas the maximum velocity threshold is higher than with the Y-pattern wiring. Star windings are inferior in terms of maximum speed, but deliver considerable moment of force even at reduced RPM. The general assumption is that the the Y-type is more efficient.

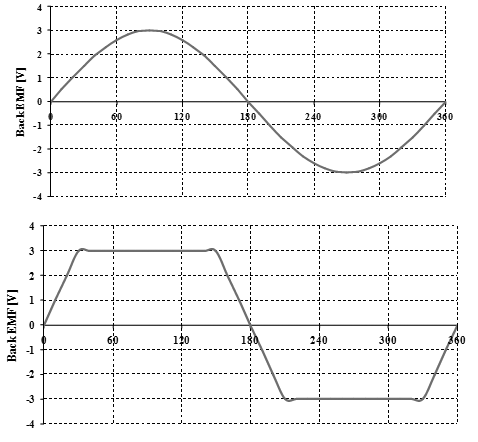

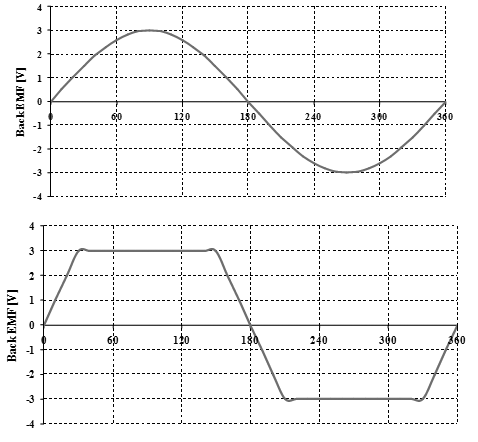

Within the brushless permanent magnet category, it is also possible to distinguish DC and AC synchronous motors. The engines have identical structural design: a rotor with ferrite or rare-earth magnets and a stator—no brush-and-сommutator assembly. Both the DC and AC brushless actuators are synchronous, meaning the magnetic fields, whether on the stator or the rotor, spin at identical frequencies and velocities. However, stators are wound in different patterns, entailing differing back electromotive force (EMF) profiles.

Technical details:

Back electromotive force is a phenomenon associated with electromagnetic induction, when specific voltage quantities flow across a conductor, opposing the change in applied current.

Rare-earth magnets are crystalline alloys containing rare-earth elements. Boasting excellent magnetic anisotropy, the magnets can deliver twice as much attraction force as compared to ferrite counterparts.

The stator of DC engines has winding of trapezoidal configuration producing a trapezoidally shaped back-EMF wave. Employing the sinusoidal winding pattern, AC actuators generate sine-shaped EMF waves, accordingly, which enables them to rotate smoothly while minimizing torque ripple. On the downside, the sinusoidal control relies on more complex algorithms than the trapezoidal one. Simultaneously, the trapezoidal configuration is associated with substantial audible and electrical noise.

FMI brushless AC motors

The motors in the FMI series by Rozum Robotics boast proprietary design:

- Brushless commutation minimizes friction-induced power losses, ensuring low-noise and spark-free operation and greater motor controllability

- Durable and robust construction with a hollow shaft facilitating integration

- Star winding allows for keeping up torque delivery even at slow rotation rates

- With basic inrunner configuration and rare-earth magnets enables achieving ultra-high efficiency in compact dimensions

- Pertains to the AC synchronous subtype, providing smooth rotation without excessive cogging, noise, or electromagnetic interference

- Temperature-sensing elements built into the rotor coils watch out for overheating to prevent demagnetization

- Superior power-to-mass ratio, torque density, enhanced efficiency, and less trouble with maintenance—that’s what you get with an FMI motor.

Related reading