The customer, a European company, needed a compact motor to provide precision rotary motion of a pneumatic gripping device integrated into an industrial machine. It turned to Rozum Robotics for in-house expertise in engineering servo drive solutions.

Challenge

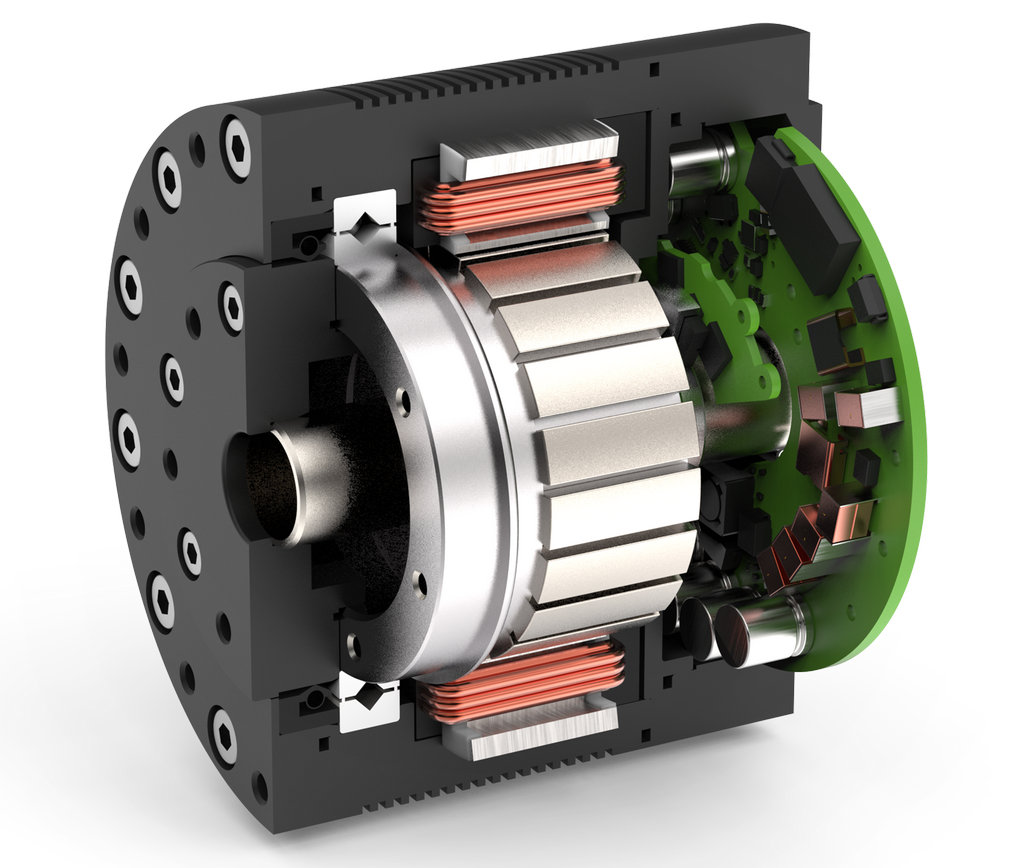

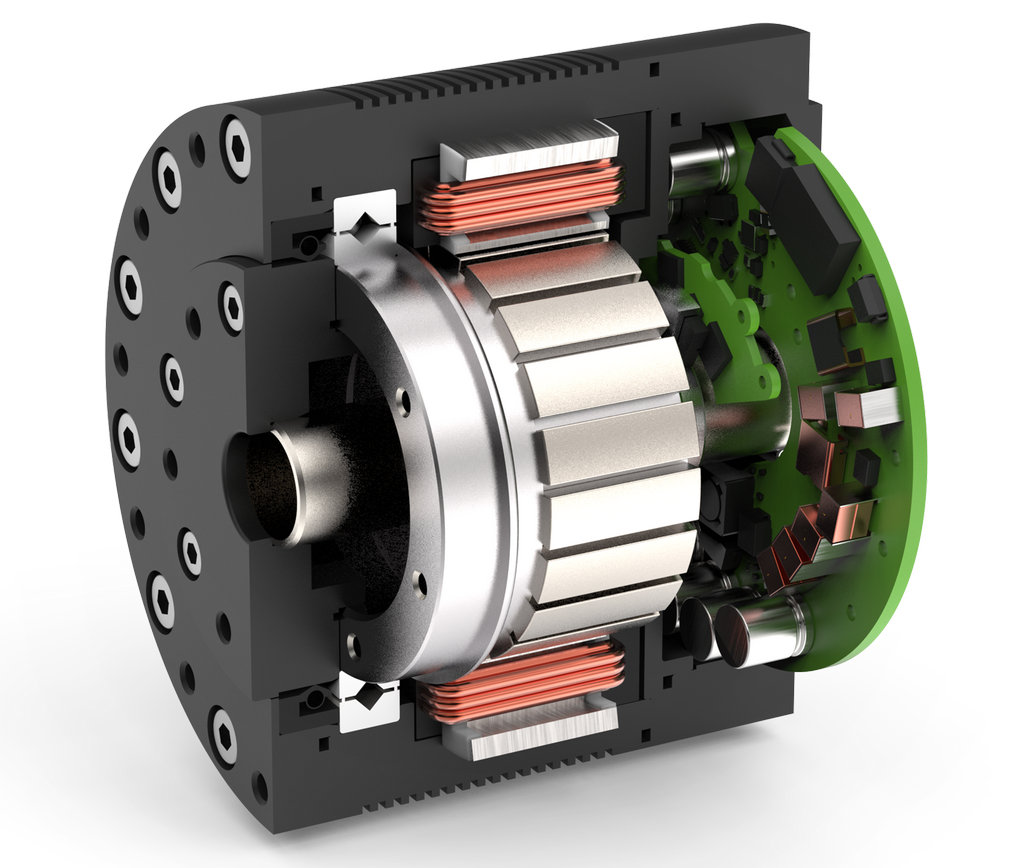

Initially, the customer opted for the gearless version of the RDrive 60 model from Rozum Robotics’ standard servo lineup. The actuator has a hollow shaft facilitating its integration and a 19-bit absolute encoder providing high-precision motion feedback. The core of the servo drive is a compact brushless three-phase motor. The motor is a stator-and-rotor kit with a torque of 300 mNm, 48V supply voltage, speed of 5,300 RPM, and an in-built temperature sensor.

The engine matched the customer demands in such parameters as availability of accurate encoder feedback, a hollow shaft, and compact dimensions. However, communication revealed a range of essential requirements beyond the scope of the above standard features:

- 200 V AC supply voltage

- Torque > 1 N•m

- Low speed

- Compatibility with a third-party external controller

- Custom mechanical and electrical interfaces for integration

In addition, the customer wanted Rozum Robotics to meet certain dimensional limitations due to the design of the end-use machinery.

Solution

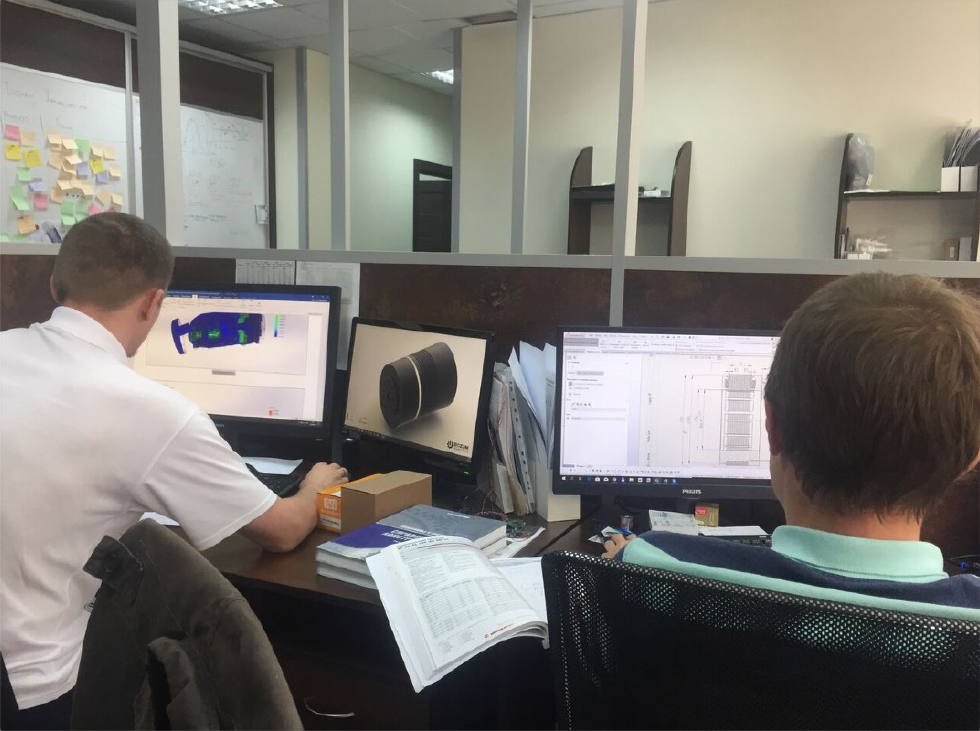

To meet the above limitations and essential requirements, the engineering team at Rozum Robotics introduced a number of modifications into the initial RDrive 60 design. The customization scope comprised the following:

Topology optimization

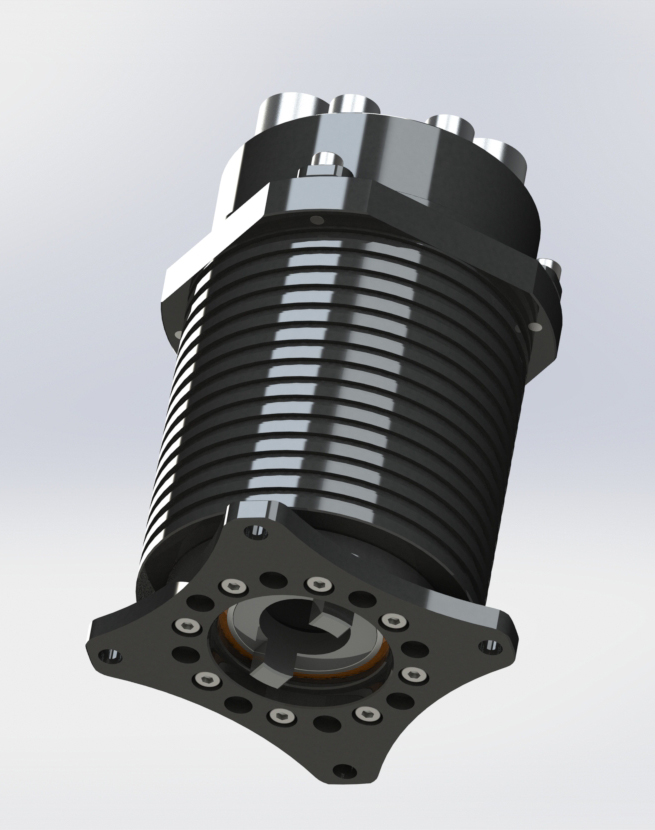

Based on the design input specified by the customer, the team re-calculated the initial engine specifications. As a result of the re-calculations, the engineers increased the stator stack height, modified the tooth profile, the winding method and pattern, as well as quantity of winding turns. For a more efficient heat dissipation, they designed a casing with custom grooving to incorporate a brushless stator-and-rotor kit.

Providing integration interfaces

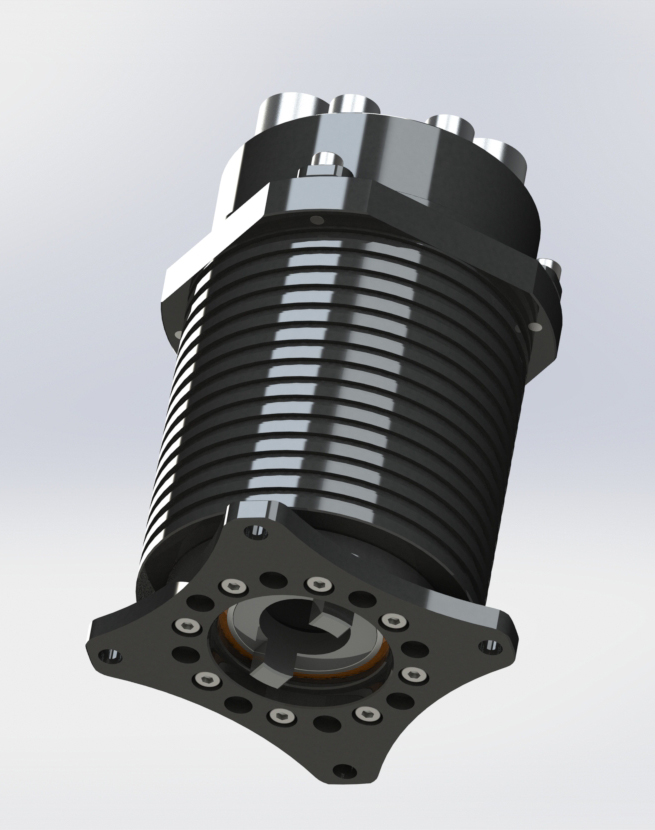

A slip ring (provided by the customer) was passed through the motor’s hollow shaft to encapsulate electrical and signal wiring. When designing the motor casing, our engineers also made provisions for analogue and digital outputs, as well as special-type mechanical fittings.

Tailoring temperature sensing

The single NTC sensor built into the stator winding as part of the standard offer was changed to three PTC sensors—one for each phase.

Outcome

As a result of the described R&D efforts, Rozum Robotics developed and manufactured a functional engine prototype in accordance with customer specifications within 2 months.

The topology optimization enabled achieving the torque output of 1 Nm and reducing the speed without a gear, while also meeting the 220 V AC supply voltage requirements. In addition, the motor dimensions were decreased to match the installation dimensions of 96 mm and 700 g accordingly.

Inserted into the hollow shaft, the slip ring acts as an interface to connect electrically the machinery, the driven load (the gripping device), and the drive, preventing wire twisting. Via the provided special-type analogue and digital output connectors, the motor wiring is lead through the hollow shaft to the load.

The custom mechanical interface on the motor casing enables seamless motor integration with the load and the machinery. Replacing a single NTC element with three PTCs improved overall solution safety, making it possible to detect short-circuiting and prevent winding damages more efficiently.