You’ve got a CNC machine for your production. Finally! Full automation, no human factor and high productivity 24/7. We are really sorry to say it, but no. Your journey into the world of automation has just started. And the ticket for this journey is the CNC robotics. Before describing all the benefits a robot brings to your CNC production let’s have a look at the history.

What are the CNC Machines?

Wikipedia defines CNC as a computer numerical control developed for machining. A CNC machine processes a piece of material by following a coded programmed instruction without a manual operator.

A program-driven production line surprises no one today. But the principle of CNC is pretty old, it goes back to 1804 and since then, there have been no fundamental changes to the approach.

The grandfather of the CNC machine was a Frenchman and a weaver. Joseph Marie Jacquard was the first to use a punched card to control the weavingmachine. The program was stuffed with binary code: hole on the punch card = action, no hole = no action. Thus, it was possible to automate the production of textiles with a variety of patterns. Many thanks to Mr.Jacquard. His invention allowed your grandmother to buy this monstrous jacquard armchair.

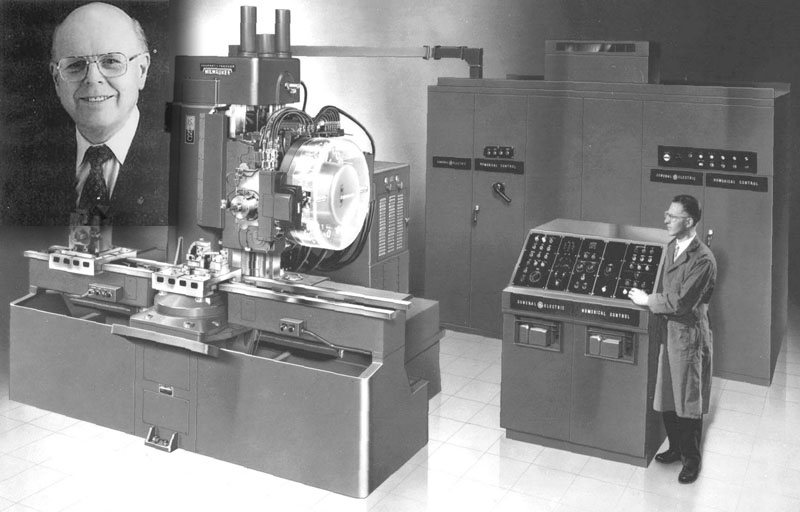

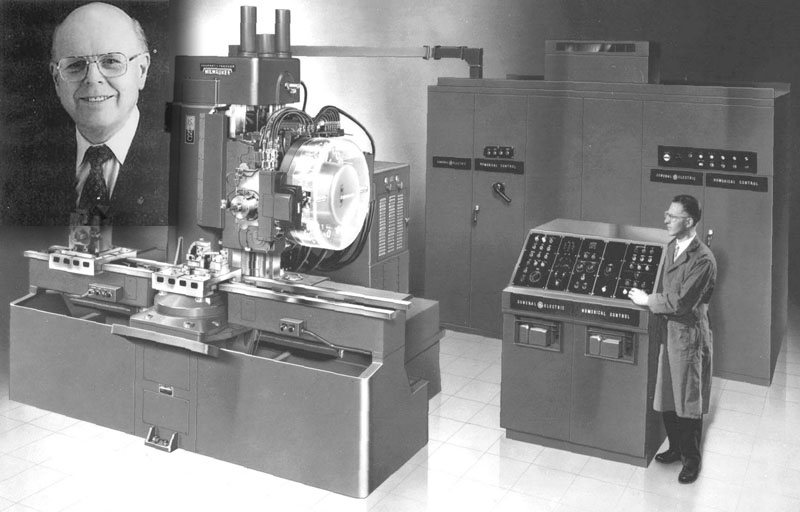

More than a hundred years later, John T. Parsons captured the Automation Banner. He came up with how to automate the production of propellers for aircraft, using the coding on metal punched cards. In the 1940s, the efficiency of metalworking and manufacturing was, to put it mildly, relevant. Later, when it turned out that the invented machine is too expensive, Parson was fired. But don’t worry - justice triumphed. It turned out that in the post-war period automation still brings huge profit. Parson's patent was acquired by such companies as IBM, Fujitsu, General Electric. The father of automation returned to the presidency chair. Automation was in the air.

CNC machines have become the striker of the scientific and technological revolution of the 20th century. Further development of the CNC control went hand in hand with the new programming languages and computing systems.

CNC machines have become the striker of the scientific and technological revolution of the 20th century. Further development of the CNC control went hand in hand with the new programming languages and computing systems.

How did the CNC Machines change our world?

- They made it faster, much faster

Are you running out of spare parts or is something broken? Today you don’t have to wait three months until the only master in the whole neighborhood carves out the necessary part. Depending on the complexity, the new part can be made in just a couple of hours. A CNC machine doesn’t need lunchtime or suffer from hangover. It just does what it was coded for, without getting tired or complaining. Top CNC machines producers are constantly looking for doping for their products. How to make it faster? More effective? Thanks to CNC machines, Amazon warehouses are always full, and you do not have to wait for your order for years.

- They made it more reliable. Fewer alarms and fewer surprises

In the good old days, the master had to spend many years learning how to produce two items that are at least similar to each other. He had to spend even more time teaching this skill to his stubborn apprentices. Before the CNC machining, no relevant quality standards existed. With the CNC machining mass production of hundred copies with microns accuracy is no longer a problem. Mr. World CNC Lathe works with an accuracy of 0.2 microns.

- They made it more affordable

The pricing policy is simple. Supply is equal to or greater than demand? The price decreases. CNC machines made millions of products more affordable. Hand-made products today are a sign of elitism, like a Lamborghini Reventon or Japanese yosegi furniture.

- They made it safer

Welding, work with metals, and cutting are always associated with high risks. Falling eyesight, bad hearing, injuries and burns. You can fix the CNC machine, but not a man. CNC machine operators face fewer risks than their predecessors. The vast majority of machines are equipped with an emergency stop button, curtain guard, soundproof casing, and guard fence.

Types of CNC Machines

Drilling, cutting, flattening, grinding, and welding. Everything that was once done manually and took time and health became simple and quick. Normally, a single CNC machine is suited to one task. Multitasking machines are more expensive and more difficult to maintain. Therefore, at large factories with a full production cycle, the whole streets of CNC Machines are built and each ‘house’ has its operation. A kind of CNC manufacture with a division of labor. To navigate in a modern huge CNC-world, you can use several differentiation approaches from the list below.

To navigate in a modern huge CNC-world, you can use several differentiation approaches from the list below.

By function

- Milling— An operator prepares and loads raw materials or parts into the machine. The CNC follows the chosen program and cuts any material precisely, considering depth, angle, and direction. In a CNC robotic milling machine, an operator is replaced by a CNC robotic arm that performs loading and unloading of parts.

- Plasma cutting — CNC plasma machine uses a tool on gas supply. This type of machine is highly accurate and fast. It slices up to 500 inches per minute. The biggest issue here is safety. CNC plasma cutter needs enough buffer-space for sparks, a good ventilation system, flame-resistant floors, and strict safety policy for operators. When using a CNC robotic plasma cutting machine, the safety is guaranteed through replacing an operator with a robotic arm. It ensures a proper machine tending without any risks for human health.

- Drilling— A machine spins and moves the drill towards a fixed part. The biggest time-wasters here can be positioning the piece and changing the drill. What an operator has to do manually, a robotic arm performs automatically by communicating with the CNC tool. The positioning accuracy of a robot results in a high-quality product.

- Welding — Delegate one of the most dangerous tasks in your production to a CNC machine. However, an operator still will still face potential hazards such as gases, fumes, fire, and explosions. Replace a human operator with a CNC robot welding machine. It will allow you to increase positioning accuracy, reach long-lasting results, reduce labor costs and risks, and gain more profit.

- Grinding — Grinding is one of the finishing processes in the modern industry. CNC machines use a rotary wheel to abrade the material into the programmed shape. Some producers offer machines with multi-part grinding options.

- Lathing – It reminds the grinding process described above. But here the machine rotates a part against an abrading tool. CNC lathes are used mainly for the manufacturing of symmetrical cylindrical objects made of wood, plastic, mild or stainless steel.

- Multitasking – Shiva in the CNC world. A single machine that enables multiple operations. It is not easy and not cheap to create such a technology where a part can go the whole way from raw material to the ready part. It is even more complicated to teach an operator to effectively control such a production. CNC robotics can be used as the most effective and reliable machine tending tool.

By number of axes

CNC machines have several axes of movement: linear, rotary, andboth. The number of axes determines the complexity and accuracy of operations.

- 2-axis The first CNC machines were biaxial, and it was possible to program actions only in X and Y. Some of the simplest CNC machines today still have only 2 axes.

- 3-Axis Most of the modern CNC milling and engraving machines have three axes. They operate X and Y horizontal, as well as the Z vertical axis.

- 4-Axis A 4-axis machine includes one more rotary axis movement, which allows operating along thearc.

- 5-Axis Three perpendicular + 2 rotary axis movements. The launch of 5-axis CNC machines allowed the producers to carry out several operations on a single machine.

- 6-Axis Three perpendicular + 3 rotary axis movements.

- 7-Axis The modern 7-axis CNC offers multiple and complex operations. Combined with a robotic arm, the machine can handle even 3D modeling. Some 7-axis CNC robotic engraving machines are already used at the design and architecture agencies.

By accuracy grade

- Normal grade

- High-accuracy grade (H)

- Precision grade (P)

- Super precision grade (SP)

- Ultra precision grade (UP)

By automation level

Semi-automated. Production steps are completed by the CNC machine, but some steps can be performed only by human or robot operators:

✔ loading raw material into the machine

✔ controlling the process

✔ unloading the ready parts

✔ controlling the product quality

Automated (CNC robotics)

All CNC machines described above allowed the industry to be more independent, autonomous, and effective. But… Your production is still under the influence of the human factor. A CNC operator may distract, ignore safety rules, or make mistakes. But not a robot.

A robotic CNC arm can load any CNC machine. It controls the whole process and unloads the machine after it’s done. It can check the finished product and pack it. A robotic operator can even move parts from one machine to another. The core features of robots are their precision, repeatability, and flexibility. To use a robotic operator means to take all the advantages of your CNC machine.

CNC robotics Or why you shouldn’t be satisfied with CNC automation alone

Robotics and CNC machines were developing in parallel. Now they are often compared as concurring solutions for industrial automation. What is better, more accurate and efficient to use?

Let’s have a look at the main CNC and robotic arm features.

A CNC machine:

- Can be programmed for a limited amount of operations

- Has a stiff and stable construction

- Has a great level of accuracy

A robotic arm:

- Can be programmed for several operations

- Is flexible and easy to move

- Has a great level of accuracy, can perform pick-and-place operations

You don’t have to exchange your existing CNC machine with a robot, but you can upgrade it. Loading and unloading, quality control, and ready parts packaging cannot be done by a CNC. But a robotic arm can perform these actions, from loading to packaging. Don’t limit your business - use the advantages of both technologies and create an automated production cycle. A robotic arm can increase the CNC cell’s efficiency.

How does a robotic arm assist a CNC cell?

- The robotic arm takes a piece and places it in the CNC machine workspace.

- A robot closes the door of the CNC cell or gives a signal to close the door automatically.

- The robotic arm communicates with the CNC machine, chooses the operation, and the production cycle starts.

- After the CNC sends a signal to the robot that the operation has ended, the robot grips the ready piece and puts it into the next processing cycle, quality inspection, or packs it to other ready parts.

5 advantages of using a robotic arm as a CNC operator

Efficiency

Automated loading boosts productivity without you having to hire additional personnel. The robot works 24/7, with no pauses, sick leaves or holidays. The automated loading/unloading frees up human employees for other, more sophisticated and creative tasks, such as setting up, programming, management.

Speed

The robot is quicker than the human in some operations and slower in others. However, consistency is a key point here. The robot isn’t a sprinter, it is a high efficient marathon runner. It grabs, loads, and unloads at the same speed throughout the whole shift of its lifecycle.

Accuracy

The robotic loader is pre-programmed for accurate positioning on each step: grabbing the part from the loading table, loading it in the CNC machine, putting on the unloading table, etc. The robot arm reaches +/-1 mm accuracy in loading and unloading operations.

Safety

A robot can work in the environments that are hazardous to human health. Too high or too low temperatures, noisy or dusty production, the most dangerous CNC operations such as lathing or drilling – a robotic arm can be adjusted to any environment.

Multitasking

While the CNC machine is drilling/milling/lathing, a robotic arm can do some other operations in parallel – load the next CNC, or pack the ready product, or check its quality. The robotic arm integrated with the CNC machine can even replace tools and grippers during the manufacturing process.

What to consider while choosing a robotic loader?

|

Parameter

|

PULSE 75

by Rozum Robotics

|

PULSE 90

by Rozum Robotics

|

|

Payload determines how much a robotic arm can hold

|

6 kg

|

4 kg

|

|

Reach determines how far a robotic arm can put a part

|

750 mm

|

900 mm

|

|

Degrees of freedom determine how flexible a robotic arm can turn a workpiece

|

6

|

6

|

|

Position repeatability determines how exact a robotic arm can put a workpiece every time

|

+/- 0.1 mm

|

+/- 0.1 mm

|

|

Ambient temperature determines the environment where a robot can work

|

0...35 °C

|

0...35 °C

|

|

Weight influences the installation easiness and collaboration skills of a robot

|

12.6 kg

|

13.6 kg

|

|

Non-stop lifetime cycle determines for how long a robot arm can work with no pauses

|

20 000+ hours

>2 years 3 months

|

20 000+ hours

>2 years 3 months

|

|

Programming influences the management and adjusting simplicity

|

Hand-guiding. REST API. UI

|

Hand-guiding. REST API. UI

|

|

Warranty

|

1 year

|

1 year

|

|

Price

|

21,839.00 $

|

25,864.00 $

|

The robotic arm solves the lack of specialists problem. No training or hiring wonders needed to put a robotic arm as a CNC load assistant. A CNC robot is easy to set up and to adjust to the new needs.

CNC machines have become the striker of the scientific and technological revolution of the 20th century. Further development of the CNC control went hand in hand with the new programming languages and computing systems.

CNC machines have become the striker of the scientific and technological revolution of the 20th century. Further development of the CNC control went hand in hand with the new programming languages and computing systems.  To navigate in a modern huge CNC-world, you can use several differentiation approaches from the list below.

To navigate in a modern huge CNC-world, you can use several differentiation approaches from the list below.