Building motor-driven machinery typically comes to rummaging the bulk of market offers to find a solution meeting the criteria: extended life, affordable price, and praisable performance. Let us see how AC gear motors fit into the selection paradigm and what are the assumptions to get applications up to peak productivity and efficiency with the actuators.

On the inside

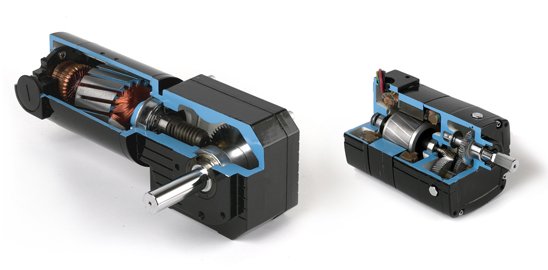

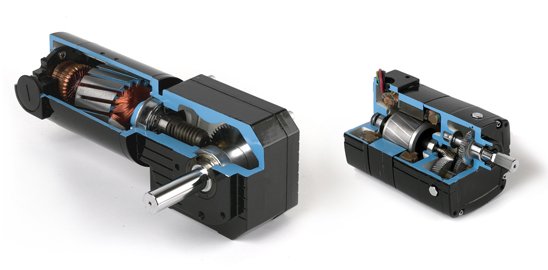

Alternating-current gear motors are fully integrated drive mechanisms comprising an electric motor (e.g, induction, synchronous) and a gearbox. Because a low-inertia rotor inside the engine is fine-tuned to match the gearing characteristics, the assembled actuators are characterized by excellent dynamics. This is a huge advantage in systems with frequent start-stop cycles. Additionally, the integrated design enables compatibility with inverters, transforming direct current to alternating—an opportunity to use different supply sources.

Gearmotors are more robust than loosely coupled user-integrated drive-reducer units. The quill mount (as in the figure below), typical of such integrations, is less costly than a gearhead with an external input shaft. Reducers with this mount have only one bearing carrier—at the engine output, which results in heavy axial loads, leading to early bearing breakdown.

Gears and electric motors making up gearmotors are sealed at factories to avoid contamination with foreign substances (e.g., water, dirt, grease). Therefore, they have high ingress protection ratings. Misalignment or broken engine-to-gear couplings are no issue since alignment under the actuator hood remains essentially the same as provided at the factory.

Best-fit applications

AC gear motors can do a good job in one particular application, while turning things the worst way in some other. The ‘good-fit’ vs. ‘poor-fit’ distinction is related to how their capabilities and working principles correlate with prerequisites.

Major correlations are as follows:

- Incorporating parallel-shaft or right-angle reducers, the devices allow for various mounting configurations and installation methods.

- With varying voltage supplies, the electric motors operate better where stable motion and unvarying velocity are not mandatory.

- Available in single-phase and three-phase modifications, the devices are able to produce both relatively low and high starting torque accordingly.

- While being small in size, three-phase actuators boast extra efficiency and reliability. The mechanisms cater to confined-area applications with increased performance and moment of force demands.

- Launched into operation with high initial velocity, the geared actuators are a poor fit when a system functions at slow pace.

To sum up, reducer-equipped engines with AC supply are best choice if the intended application requires considerable and variable torque quantities and operates mostly at fast speeds. The actuators are a real catch when the user needs to save space or has strict dimensional restrictions.

Advantages of AC geared motors in brief

The AC-type gear-enhanced actuators possess a range of distinguishing qualities:

- Geared drives of the AC category are less bulky in size and weight than, for instance, DC ones.

- Alternating-current engines are better protected from adverse effects of explosive, damp, contaminated, or unfriendly environments.

- Velocity regulation systems used in combination with the mechanisms boast enhanced precision, enabling to manage multiple motors simultaneously.

- Control remains efficient even at the upper performance limit, reaching 10,000 RPM (or 1:1,000 gearhead ratio).

- Geared electric motors with AC supply generate stable HP quantities at up to 150 of the operating speed value.

- The mechanisms provide premium efficiency over a wide range of temperatures, including in colder environments than DC models with built-in reducers.

The last but not the least—the cost, both in terms of purchase price and operation expenses. Due to simple design and production process, AC geared motors are cheap to buy and easy to encounter. The drive mechanism of the type includes no mechanical components, such as commutation brushes, which is why are have extended service life and save users maintenance expenses.

Selection tips

When the decision is made to utilize an AC gear motor, the next move is to assess available model ranges to find out the best variant. Below are essential steps of the selection process.

- Gather application-specific requirements. As the first priority, focus on the required and admissible speed and torque ranges and modes. Secondly, consider the ambient conditions, such as contamination sources, noise levels, and temperature regimes. Secondary criteria include mounting method, envelope size, orientation, as well as expected service life, maintenance scope, and control type.

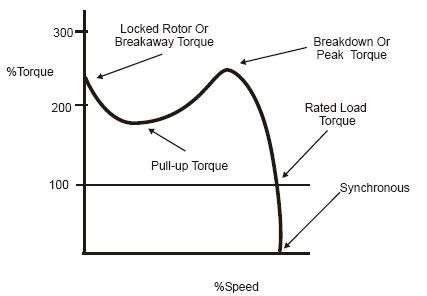

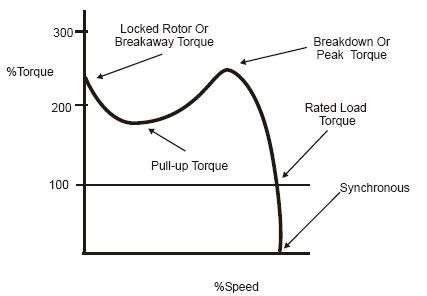

- Pick a model based on speed and torque requirements. Study thoroughly gearmotor curves from different vendors. The curves demonstrate critical performance characteristics—velocity, including at the gearbox input, and rotational force in both the continuous and intermittent duty modes. Pay attention to whether the thermal and other secondary specifications of the chosen model match the requirement gathering results.

- Make sure the yield strength, as well as breakdown and pull-up torques of the chosen device have admissible values.

Yield strength helps to understand whether a driving mechanism can handle the overall load in a machine without damaging it. Breakdown torque implies the highest moment of force available before its value drops while a machine is still within the admissible operating range. Pull-up torque is the minimum Nm output while an engine ramps up from zero to its full-load operating speed.

Assess associated risks: Extreme radial and axial stresses affecting the motor shaft damage bearings or cause fatigue failures. Excessive inertia loads and frequent alternation of acceleration/ deceleration modes contributes to increased tooth fracture risks.Gearbox operations in an unsuitable environment leads to sealing and heat dissipation issues, reducing the working lifespan of a gear motor. Unstable mounting arrangements degrade motor durability and cause alignment problems. Improper matching of motor-specific and overall system control can lead to overheating.

Assess associated risks: Extreme radial and axial stresses affecting the motor shaft damage bearings or cause fatigue failures. Excessive inertia loads and frequent alternation of acceleration/ deceleration modes contributes to increased tooth fracture risks.Gearbox operations in an unsuitable environment leads to sealing and heat dissipation issues, reducing the working lifespan of a gear motor. Unstable mounting arrangements degrade motor durability and cause alignment problems. Improper matching of motor-specific and overall system control can lead to overheating.

So, selection is rather a painful process, where it is essential to count in multiple nuances.

To save time, engineering efforts and financial resources, consider an out-of-the-box all-in-one motion solution with an AC motion core—RDrive series by Rozum Robotics.

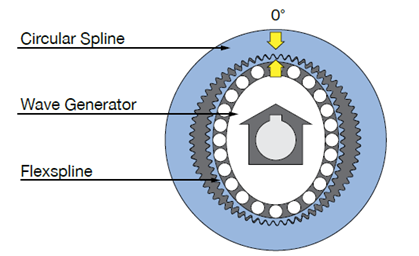

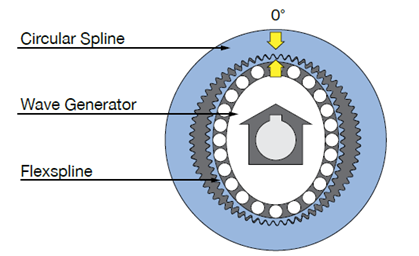

The RDrive product line includes five models of hollow-shaft gear-enhanced motors with integrated strain-wave gearheads. The perfectly matched integration saves the trouble of searching a proper gearbox to couple to a drive unit and designing the coupling. With diameters ranging from 53 to 115 mm and length 85 to 150 mm, the actuators provide mounting and orientation flexibility, while requiring minimum installation space.

Boasting almost zero backlash, built-in harmonic gearing mechanisms don’t let engines lose an inch of positioning precision. The high gearhead ratio enables multiplying the rotational force of brushless AC cores by nearly a hundred times. The prices are at the industry-average level and below—a good bargain considering performance ratings. To get torque data and other detailed servo characteristics, refer to specifications.

Assess associated risks: Extreme radial and axial stresses affecting the motor shaft damage bearings or cause fatigue failures. Excessive inertia loads and frequent alternation of acceleration/ deceleration modes contributes to increased tooth fracture risks.Gearbox operations in an unsuitable environment leads to sealing and heat dissipation issues, reducing the working lifespan of a gear motor. Unstable mounting arrangements degrade motor durability and cause alignment problems. Improper matching of motor-specific and overall system control can lead to overheating.

Assess associated risks: Extreme radial and axial stresses affecting the motor shaft damage bearings or cause fatigue failures. Excessive inertia loads and frequent alternation of acceleration/ deceleration modes contributes to increased tooth fracture risks.Gearbox operations in an unsuitable environment leads to sealing and heat dissipation issues, reducing the working lifespan of a gear motor. Unstable mounting arrangements degrade motor durability and cause alignment problems. Improper matching of motor-specific and overall system control can lead to overheating.