Miniaturization is a global trend aiming at maximizing user gains, while minimizing space, resource, and energy takeup. Companies strive for more power at lower cost and in a compact size. Small servo motors seem like an an answer to the manufacturers’ prayer. Though unimpressive in terms of dimensions, the devices deliver consistently high torque and boast stable performance over a wide range of velocities.

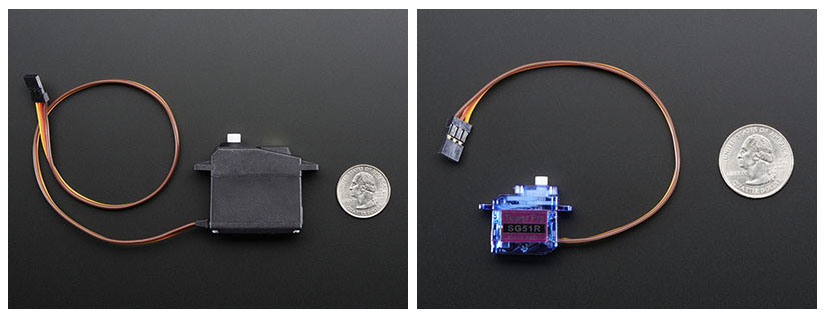

Standard vs. small servo motors

Whether of reduced or conventional size, servomechanisms are similar in the exterior looks, constituent elements, as well as the functioning principle.

On the outside

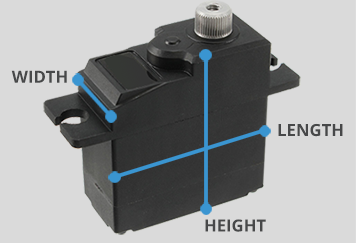

Just as bigger modifications, small servos have:

- A casing, or housing, protecting its internals from exposure to adverse conditions and ingress of contaminants (e.g., dust or moisture). Miniature models mostly comprise three plastic sections, bolted together. When an engine is really tiny, heat sinking or adhesives are more preferable methods to assemble the casing components.

- Cabling with connectors, typically comprising three wires to provide power supply and communication. Wiring color schemes vary from manufacturer to manufacturer. Commonly accepted cable gauge is 22, whereas smaller drives tend to go with thinner wires of shorter lengths.

- An output shaft coupling the drive to a machine. Servo motors are available either in hollow- or hub-shaft versions. The hollow-shaft variety is believed to ensure easier integration—all it takes is to clamp the housing onto the shaft of the driven machine. Actuators of the second type have splines on their shafts for secure attachment of accessories.

- Accessories, such as wheels or horns, providing interaction with servo-driven equipment.

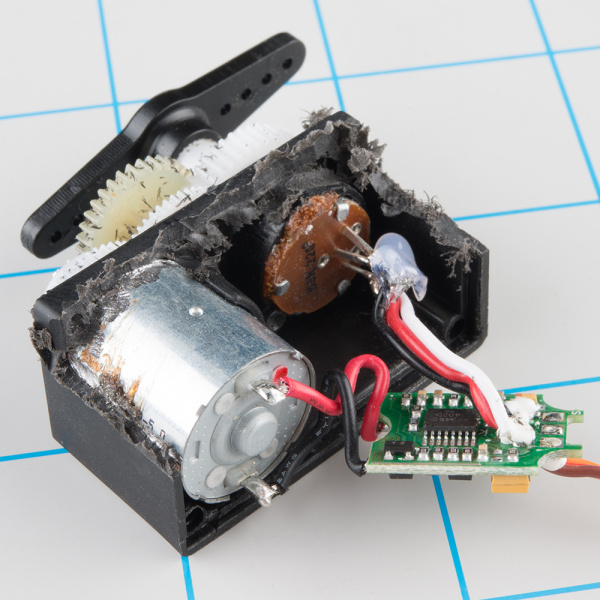

On the inside

Major sub-modules include:

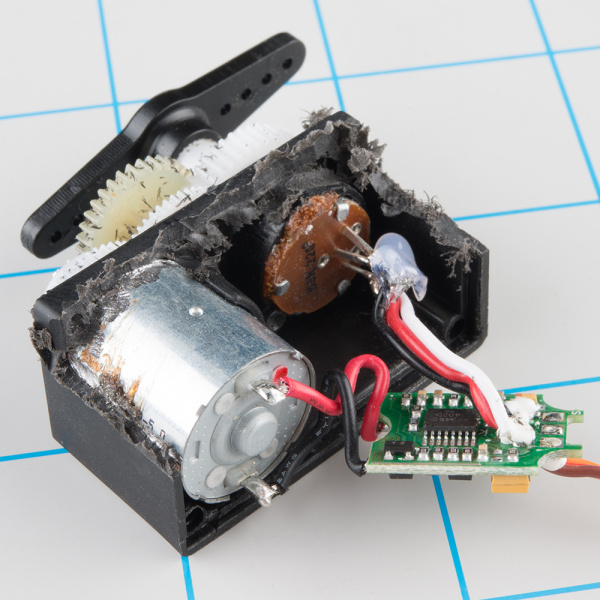

- An electrical actuation mechanism, producing rotational force (Nm) and speed (RPM) according to vendor ratings.

- A sensor monitoring positions of the output shaft—a potentiometer, a Hall-effect detector, an encoder, etc.

- A circuit board with control electronics processing signals from a master device and response from the position sensor and performing calculations to provide optimal motion parameters.

- Additionally, servomechanisms are equipped with a gearbox optimizing the output of the actuation mechanism to achieve better speed-torque combinations. Actuators of the cheaper range rely mostly on plastic gears that are less expensive and bulky than metal ones. Adding gears made from high-tech materials, other than plastic (e.g., carbonite), allows to produce considerable rotational force even in a miniature housing.

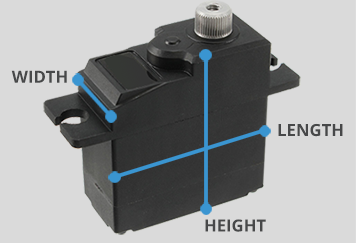

- Which one is the tiniest?

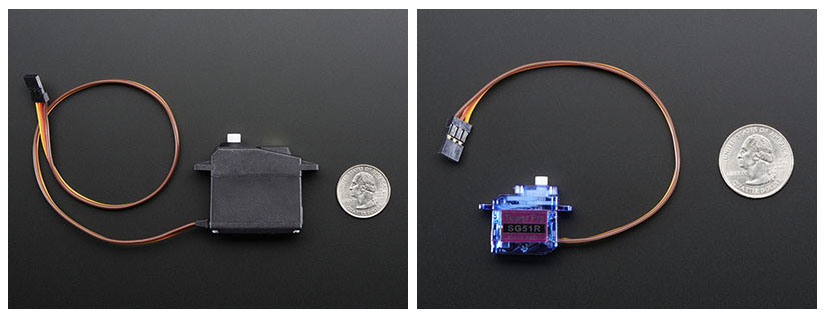

- The usual sizing classification into large, standard, and small servo motors can be expanded with a few more type names, such as micro, sub-micro, mini, and nano. The table below summarizes approximate dimensions of the subclasses based on current vendor offers.

- Nano | Weight: Up to 8 g | Length: 7.5 mm | Width: 18.5 mm

- Sub-micro | Weight: 8–16 g | Length: 11.5 mm | Width: 24 mm

- Micro | Weight: 17–26 g | Length: 13 mm | Width: 29 mm

- Mini | Weight: 27-39 g | Length: 17 mm | Width: 32 mm

Individual manufacturers come up with the pico variety featuring the tiniest dimensions and about 4 g of weight. In some catalogs, it is also possible to come across ultra-nano or giant designs.

Small, but popular across industries

Optimize and minimize—a slogan as catching as a virus around the today’s world. Therefore, small servos are in great demand in applications where miniature size, accuracy, and powerful performance are critical. In particular, the devices are widely adopted in robotics, physical computing, as well as animatronics and model building.

Physical computing refers to combining hardware and software to build interactive systems with an ability to sense and react to the physical world. Examples include augmented reality, smart traffic management, process automation solutions.

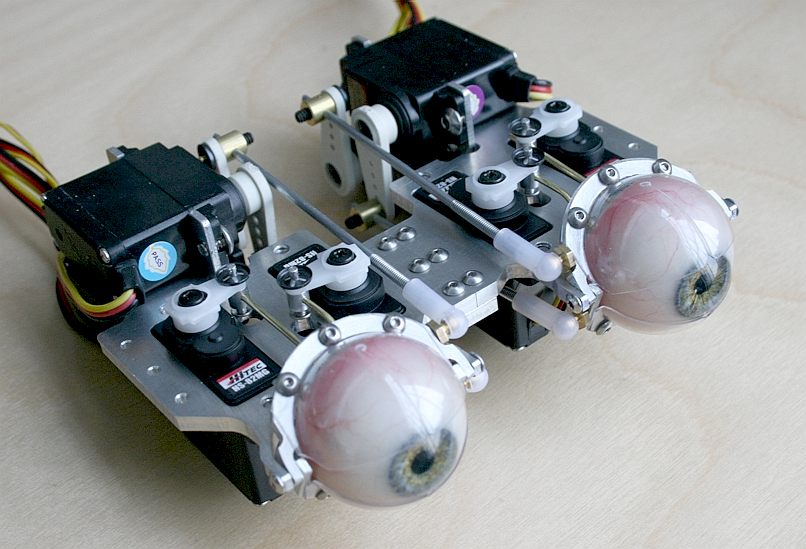

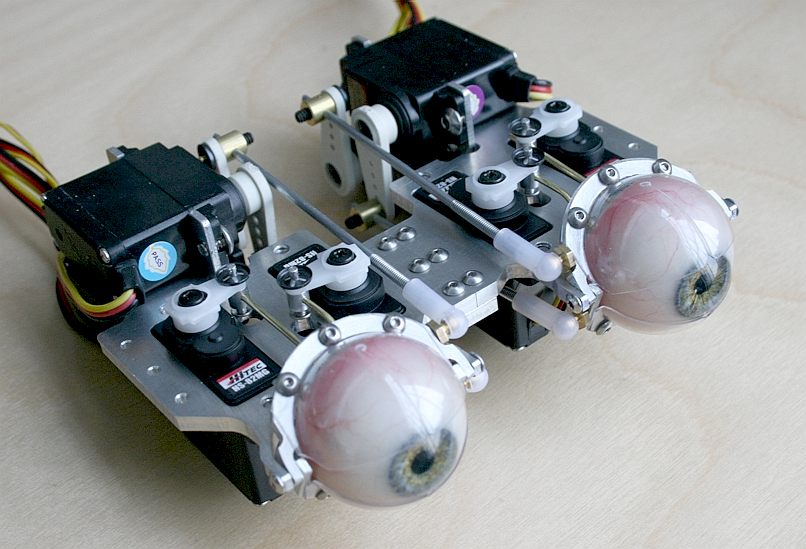

Animatronics implies using mechanical or motor-driven arrangements to emulate behavior of a human or an animal. Miniature servomechanisms move the limbs of a dummy monster in a movie or enliven fancy characters in an amusement park.

Robotics is an engineering branch specializing in designing, building, and operating robots and associated control devices. Compact in size, servo motors fit perfectly into robot joints, while producing enough torque to lift and move them repeatedly to a precise angle at a specified moment of time. The robotic actuators are quiet, efficient and support communication with external systems via embedded protocols (EtherCAT, CANOpen, etc.).

Model building, pursued as a hobby, involves constructing models of aircraft, boats, cars, etc, from special kits or individual components. The most common choice is a radio-controlled (RC) servomechanism that a modeller is able to purchase for just a few dollars. RC devices are simple to control, but limited in their motion range to 180 degrees and have certain precision issues.

Apart from the above applications, small servo motors are employed in cameras for autofocusing, as well as in automatic door openers. Advancements in mechatronics stimulate development of the medicine-oriented servo technology, including to be used inside a human body.

Compactness by Rozum Robotics

Rather than calling RDrive actuators miniature servos, one should designate the mechanisms as compact industry-grade solutions with a bunch of benefits:

- Decreased footprint and a hollow shaft to support seamless integration, no additional mechanical accessories (horns, wheels).

- Optimized power-to-weight ratio with torque delivery reaching 216 Nm in larger models.

- Robust construction—casing and gearing made from metal and two bearings supporting the integrated gearbox at the input and output.

- Programmable communication interface relying on CANOpen and feedback from absolute encoders, which makes controlling motion in an application almost effortless.

- CANOpen bus connectivity enables distributed installation of multiple driving mechanisms and their management from a single master.

Though it is unlikely that an RDrive servo can fit into a camera, the drives are an asset to heavy-duty applications demanding exceptional positioning accuracy. In particular, robots and industrial automation solutions. Animatronics specialists and modellers can also leverage the technology to be in full control of how a vehicle or a mockup moves, while adding maneuverability.

Notwithstanding the reduced size, the servos in the series have not lost an inch of precision, capable of unfailingly repeating the same moves over and over again.