From its invention in the early nineteenth century up to now, the electromotor technology has made impressive progress, winning over fans across households, industries, businesses. Medical and food processing equipment, heavy-duty pumps, compressors, agricultural and construction machinery—every application has nuances, demanding a singular approach. Modification certainly fills some gaps, but a custom electric motor allows to satisfy the entire set of system-specific demands, bringing overall productivity to a completely new level.

What makes a custom engine?

Presenting a motion solution as a custom electric motor is another way of saying it has non-standard properties. The definition implies no reference to non-conformance with normative regulations (e.g., NEMA), rather indicating a product is outside the series production range of a manufacturer.

Standard manufacturer lineups typically comprise selected off-the-shelf items of predetermined makeup and established properties. In the sense, changing either any component (e.g., adding a gear) or specification (e.g., input voltage) would make a motor custom.

Though potentially customizable features are versatile and numerous, the following customization cases are typical:

- Tailoring performance of an electromotor to expected voltage input, torque output, or thermal characteristics, etc.

- Transforming or resizing a housing to fit into a particular installation or mounting arrangement

- Upgrading configuration to withstand extreme ambient conditions (e.g., excessive vibration, submersed operation) or to observe industry-specific regulations (e.g., concerning clean rooms)

Whatever goal is set—better efficiency, low cogging, saving floorspace, the decisive argument in favor of ordering a turnkey electromotor is getting full control over the final result.

Beware stereotypes

Buying a tailor-made mechanism is a good choice, really? The answer is not obvious, though, and depends much on the precise circumstances of a potential case. However, the good sometimes turns into evil if you look at it from a wrong perspective—just as illustrated below.

They say...

- Tailoring an engine is associated with soaring expenses and extensive experiments.

- Development of a tailor-made electric engine is a painfully lengthy process.

- Maintaining and servicing a made-to-order electromotor gives consumers new bothers.

In fact...

- Custom electric motors enable running an application at its maximum efficiency. Such devices reduce wear and minimize costs related to damages due to failures or maloperation.

- With sufficient expertise under its belt, a manufacturer can modify a standard offering and ship a finished mechanism at short notice. An extra bonus is the time and troubles saved during integration, since a customized product is usually a plug-and-use machine.

- Manufacturers are liable for the outcome, whereas modifying a motor on their own, users risk losing the right to claim under warranty.

So, with a proper approach, tailoring a motion solution to individual preferences is never a waste of money, but rather a means to create added value—be it capacity or financial profit.

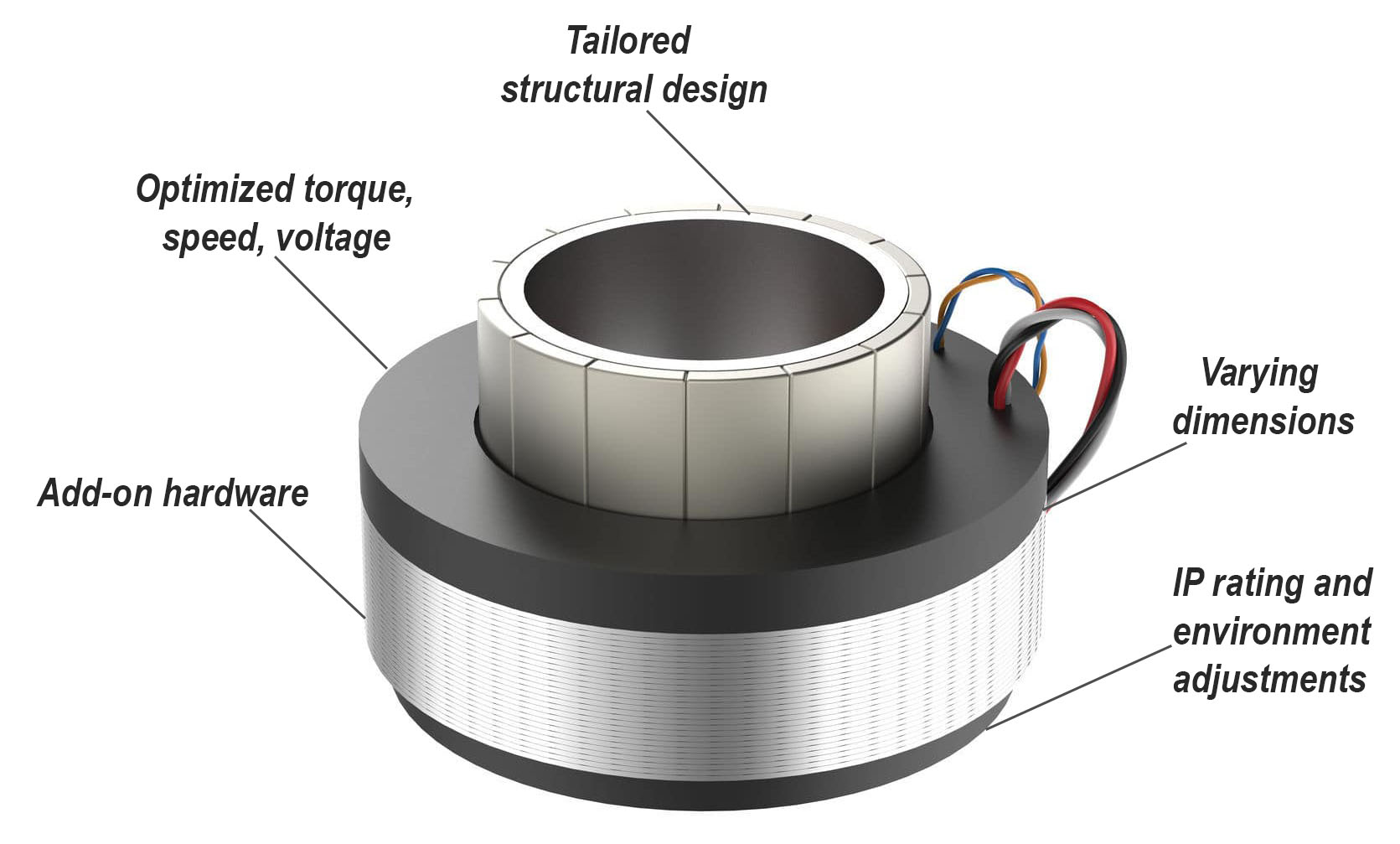

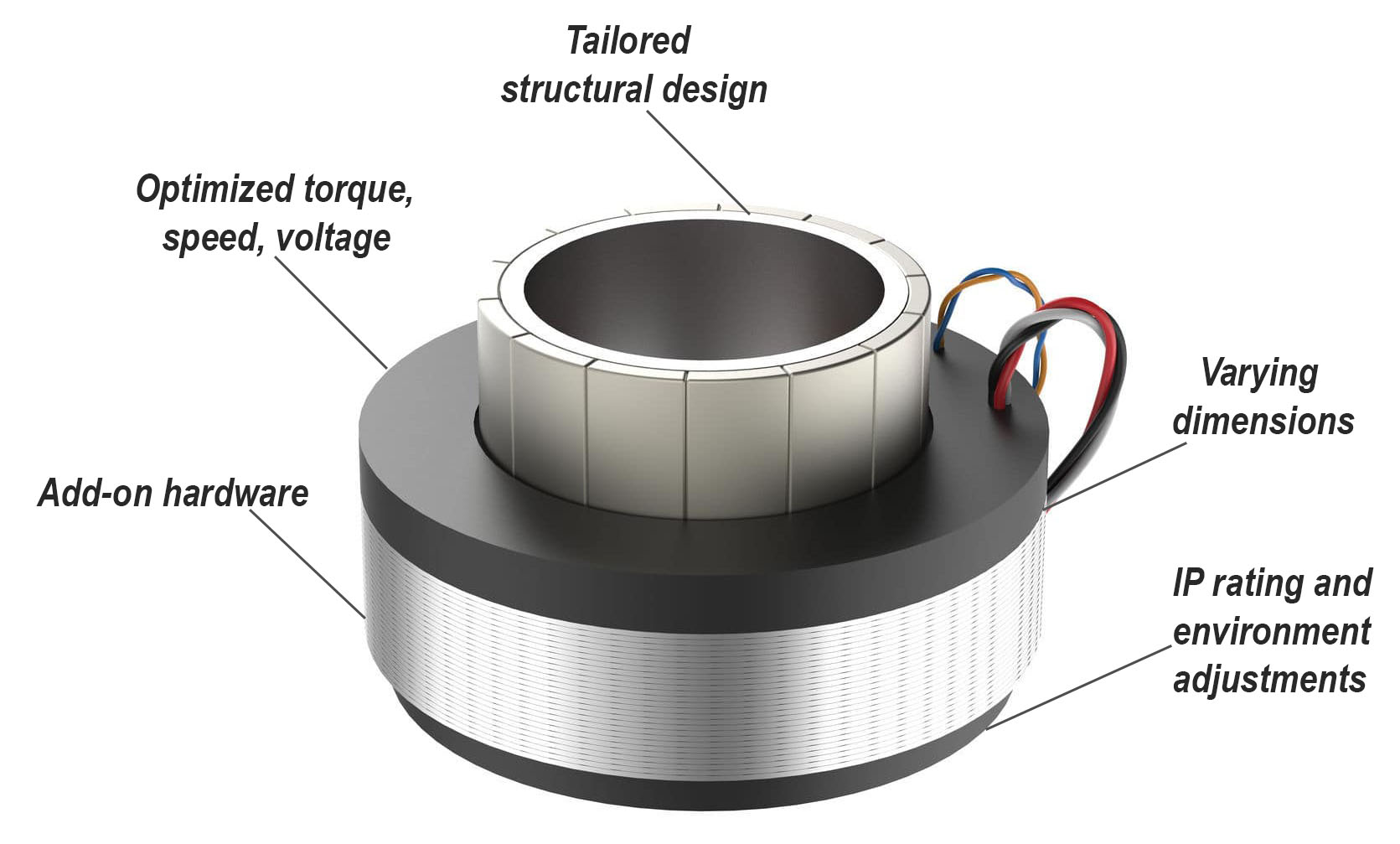

Custom electric motors based on FMI series

Rozum Robotics provides customization services based on its standard lineup of frameless motors. With assistance from the company’s specialists, you can get exact-fit electric engines to suit priority requirements in a system without compromising on any critical or minor features. Customization offers encompass the following:

Varying dimensions | Available frameless diameters vary from 30 to 100 mm, whereas the height of the rotor stack ranges from 5 to 71 mm.

Optimized torque, speed, and adjustable input voltage | Depending on the user-side power system, FMI engines allow to work with 12, 24, 48, and 220 Volts power sources. Our engineers are ready to upgrade or degrade torque and velocity output to exact consumer needs.

Tailored structural design

In the basic configuration, FMI motors are inrunners with magnets glued to a ringed rotor that spins inside a fixed-in-place stator. Outrunnerconstruction is also possible upon request, in which case the stator is located inside a moving rotor ring.

Users have an opportunity to choose between the Delta- or Y-type winding, T- or I-shaped teeth, as well as straight or skewed configurationsof the stator. For the rotor, two types of magnets are on offer—neodymium or samarium-cobalt.

The wiring connection is either on the back or on the side, with its maximum length reaching 200 mm. Wiring insulation is available in polyvinyl chloride, polyolefin, or fluorinate versions. Connector types include terminals, soldered contacts, and Molex.

Add-on hardware

FMI-series actuators incorporate a thermal protection device, which is a negative temperature coefficient (NTC) sensor by default. Alternatives are a positive temperature coefficient (PTC) sensor, a semiconductor-based KTY detector, or a thermal switch. No temperature sensing equipment is also an option.

Adding an air or another cooling module to the actuator body allows to boost power and efficiency. Additionally, Rozum Robotics supplies custom frameless motors encoder-ready or with a Hall sensor, enabling users to obtain position feedback.

Furthermore, customizable features cover environment adjustments and changing the IP rating. Based on FMI frameless motors, our specialists can assemble a custom servo, featuring a made-to-order housing, fittings, or in combination with or without a controller and gearbox.

Customization procedure

No matter at what stage you are at the moment—just got a brilliant idea or already elaborated a concept—Rozum Robotics is ready to assist in implementing your project. We carefully guide buyers through all steps to deliver a custom electric motor to your preferences:

Step 1. Requirement gathering

The company’s experts cooperate closely with the customer to specify performance parameters to attain, including desired speed, torque, and other duty cycle details. We advise the client on the best combinations of custom options, giving recommendations on providing a system to control motion.

Step 2. Designing a turnkey solution

Once the end user confirms gathered requirements, our team sets off to develop outline drawings, taking into consideration requested motor parameters. At the stage, we communicate actively with the customer to eliminate bottlenecks, clarify outstanding or suggest amendments to the initial design, if those prove necessary.

Step 3. Building and testing a prototype

Experts at the company deliver a sample electric motor and test its parameters to check compliance with custom specifications.

Step 4. Assisting in integration and follow-up servicing

Finally, the resulting product is supplied to the end consumer as a plug-and-use device, accompanied with tips to ensure seamless and quick integration. After-sale servicing is in accordance with established warranty terms. In addition, we are willing to provide any further assistance or consultations upon demand.

Rozum Robotics implements a totally flexible approach: instead of focusing on the standard features in stock, we create exact-fit solutions to satisfy our clients’ needs.