Controllers are the core of the closed-loop motion control system integrated into the housing of the RDrive servo motor. The device closes the loop by monitoring the feedback signals from two position encoders and applying a command current to control the motor.

How the controller enables motion control

In a motion control system, controllers are usually involved in the following control interactions:

- They receive command input from a control device (e.g., PC) and, based on the input, create a motion profile. This motion profile is a sequence of position commands versus time. Controllers rely on the profile to generate torque signals and apply them to the motor, telling it where to move the load and how fast the movement should be.

- They monitor the signals from a feedback device (e.g., encoder) that tracks the motor motion and compares them with the input commands from the control device. When required, they adjust the motor position and speed to match the input parameters.

How controllers work in RDrive servo motors

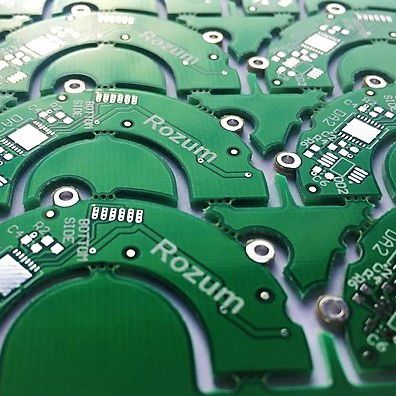

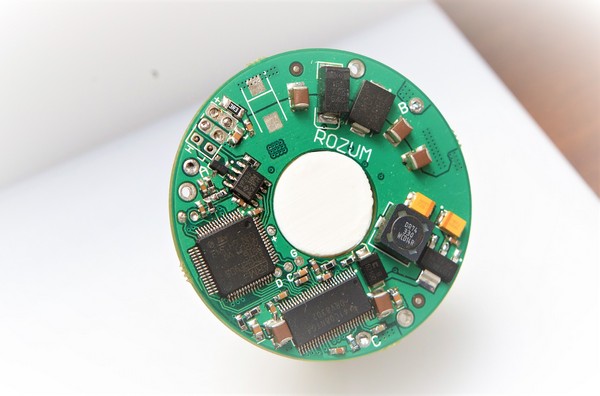

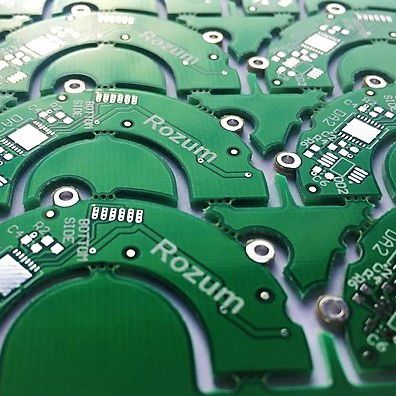

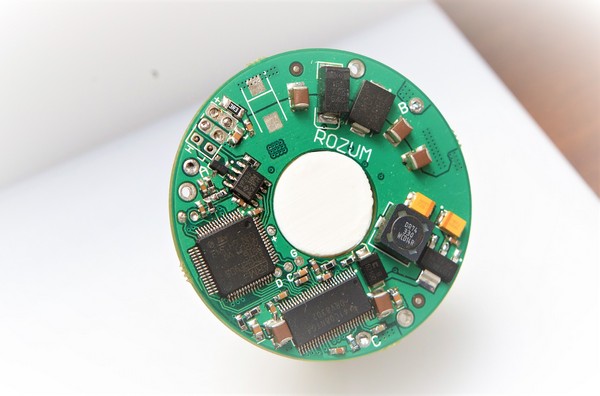

The controller used in the RDrive servo motor is an in-house development of the Rozum Robotics company. We started with just an idea to design and build a servo that would be both compact and ensure efficient motion control.

To manufacture the controllers, Rozum Robotics purchases the consumables (resistors, microchips, etc.) from reliable suppliers and mounts the components onto a printed circuit board (PCB). The PCB is then integrated into the servo motor housing. Such integration not only saves space in your machine, but also eliminates excessive cables and connectors and improves electromagnetic compatibility.

In the motion control systems of the RDrive servo motors, the controller receives feedback signals from the two built-in encoders. Communication between the two is done by means of a BiSS line. The feedback includes data on the angular motion and speed of the servo’s output shaft as well as the angular positions and speed of the rotor shaft.

Based on the information, controllers determine whether the frameless AC motor has reached the required position and speed. Depending on the results, the controller corrects the motor’s behavior as needed. They also receive commands from the control device, communicating with it over a CAN network.

In combination with two absolute magnetic encoders, the controller forms an all-in-one compact motion control solution that allows for precise positioning even in tough environments.