- Company

- Products

- Blog

-

Rozum Café

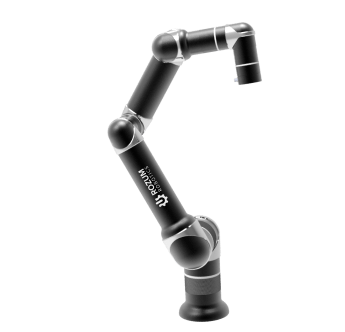

Rozum Café

The 1st coffee solution developed around a robot barista. The robot brews great coffee 24/7 and needs less than 3 min for a cup. It’s a reliable business with a ROI period that is under 9 months.

Coffee solution developed around a robot barista.

Visit Website